Vertical Form Fill Seal Machines

Our Vertical Form Fill Seal machines(VFFS) are the culmination of TAM's more than 50 years of experience and expertise.

Vertical Form Fill Seal machine(VFFS) forms bag from film and fills an assortment of products such as powders, granules, and pieces, which come in a variety of shapes and kinds of foods such as candies, coffee beans, frozen foods and snacks by dropping vertically. We are experts in this area of filling, offering machines capable of handling zip-lock bags for temporary storage, highly functional bags, such as bags with valves; and perform gas-filling capabilities, achieving the utmost level of value-added packaging which meet customer’s requirement. Our wide variety of product range also offer simple and economical models with basic Vertical Form Fill Seal machine(VFFS) functions but also have robust frame structure made in Japan.

Integration of Vertical Form Fill Seal machines(VFFS) with auger filling machine is also one of our main field. We offer the best solution to meet product character such as the product is free-flow powder or non free-flow powder.

From our long years experiences, option devices to accommodate with the product shapes, nature and wrapping material and required wrapping speed can be added. Feel free to ask us, then Tam offers suitable automatic packaging machine or system to meet the customer's requirement.

Compatible Bags

|  |  |  |  |

| Flat bag | Wide top bag | Zip bag | Block-bottom bag | Gusset bag |

|  |  |  |  |

| Quattro pack | Hem seal | Punch-hole bag | Chain bags | Three-sided-seal bag |

Next-Generation Vertical Form Fill Seal Machine(VFFS)TWFX

Features

TWFX is desined as our V.F.F.S next-generation model which has intelligent functions such as automatic film meandering correction device even in high-speed production, contamination detection by the end seal 2-axis servomotors, and film-end forecast & announcement function. Maintenance of the machine can be efficiently carried out by widely accessible structure and LED lights located inside. Usability for operator has been improved in film change and format change.

specifications

| Bag Size Range | Bag Width | 50 - 200mm |

|---|---|---|

| Bag Length | 50 - 300mm | |

| Packaging Speed | Max. 120 bpm | |

| Machine Dimensions | W 979 x D 1741 x H 1420 mm | |

| Machine Weight | Approx. 800 kg | |

A New Japan-basic Vertical Form Fill Seal Machine(VFFS), Continuous motion TWJC

Features

TWJC is a model pursued 'Made in Japan quality' with high performance and affordability.

This continuous VFFS is equipped with servo-driven seal mechanism which will produce stable seal strength even at high-speed operation.

By combination with a hem folding device(optional), 4 side corners Hem seal bag can be produced.

specifications

| Bag Size Range | Bag Width | 80 - 250mm |

|---|---|---|

| Bag Length | 80 - 300mm | |

| Packaging Speed | Max. 140bpm/flat bag, 90bpm/gusset bag | |

| Machine Dimensions | W 1200 x D 1955 x H 1575 mm | |

| Machine Weight | Approx. 700 kg | |

A New Japan-basic Vertical Form Fill Seal Machine(VFFS)TWJB

Features

The TWJB is an ideal model, combining both "made in Japan" quality with affordability. Designed with the aim of holding costs down, the high-performance model of the TWJB, which comes factory installed with major functions, can be used "as is" and achieve optimum cost performance. This intermittent model can produce 100 bag/min, sealing quality is secured by servo-driven 2-link end-seal heater system and smooth film feeding by adopting vacuum chamber type film tensioning unit.In case of usage by combination with our FRJB Auger filling machine, the operation can be controlled by one integrated control panel.

specifications

| Bag Size Range | TWJB3 | Bag Width : 50 - 220mm |

|---|---|---|

| Bag Length : 50 - 300mm | ||

| TWJB8 | Bag Width : 100 - 300mm | |

| Bag Length : 50 - 410mm | ||

| Packaging Speed | Max. 100bpm | |

| Machine Dimensions | TWJB3 | W 1121 x D 1939 x H 1413 mm |

| TWJB8 | W 1426 x D 1944 x H 1673 mm | |

| Machine Weight | TWJB3 | Approx. 620 kg |

| TWJB8 | Approx. 730kg | |

"Quattro Pack" Vertical Form Fill Seal Machine(VFFS)TWQ

Features

This Vertical Form Fill Seal Machine(VFFS)machine can be used to produce flat-bag, quattro-pack, and three-sided seal bag. It has robustness following the vertical pillow-pouch filling machine, and moreover, is capable of handling diverse product shapes and still fit within confined space. Changeover from flat-bag to quattro pack is easily possible by swiveling the end-seal unit.

Specifications

| Bag Size Range | Bag Width | 40 - 95mm |

|---|---|---|

| Bag Length | 45 - 130mm | |

| Packaging Speed | Max. 100bpm | |

| Machine Dimensions | W 985 x D 1466 x H 1350 mm | |

| Machine Weight | Approx. 775 kg | |

*Three types of pillow pouches can be produced by one machine.

Standard & Snack Specifications

Vertical Form Fill Seal Machine(VFFS)TWN3

Features

This standard but very functional vertical form-fill-seal machine was created based on TAM's pursuit of exceptional film feeding and sealing performance. When the machine is running, operators can view the operating status and monitor the temperature, pressure, and closure location on the sealing bar.

Both continuous and intermittent model are available based upon requirements.

Specifications

| Bag Size Range | Intermittent type | Bag Width : 65 - 250mm |

|---|---|---|

| Bag Length : 50 - 300mm | ||

| Continuous type | Bag Width : 65 - 250mm | |

| Bag Length : 100 - 300mm | ||

| Packaging Speed | Intermittent type | Max. 100bpm |

| Continuous type | Max. 140bpm | |

| Machine Dimensions | W 1184 x D 1846 x H 1600 mm | |

| Machine Weight | Approx. 900 kg | |

Standard & Snack Specifications Compact Machine

Vertical Form Fill Seal Machine(VFFS)TWTT

Features

The TWTT is smaller in size compared to the TWN standard machine, being 140mm lower in height.

Specifications

| Bag Size Range | Bag Width | 50 - 200mm |

|---|---|---|

| Bag Length | 50 - 300mm | |

| Packaging Speed | Max. 100bpm | |

| Machine Dimensions | W 1085 x D 1846 x H 1420 mm | |

| Machine Weight | Approx. 800 kg | |

Coffee & Powder

Vertical Form Fill Seal Machine(VFFS)TWN5 ⁄ TWN6

Features

These two machines easily fill a variety of granular products such as coffee beans and ground coffee; various types of products in powder form such as flour; and other products such as spices ,instant soups and chemical powder. By attaching TAM's auger filling machine, you can manage various operations, from filling to packaging.

Specifications

| Bag Size Range | Intermittent type | Bag Width : 65 - 250mm |

|---|---|---|

| Bag Length : 50 - 300mm | ||

| Continuous type | Bag Width : 65 - 250mm | |

| Bag Length : 100 - 300mm | ||

| Packaging Speed | Intermittent type | Max. 100bpm |

| Continuous type | Max. 140bpm | |

| Machine Dimensions | W 1184 x D 1948 x H 2922 mm | |

| Machine Weight | Approx. 1170 kg | |

Vertical Form Fill Seal Machine(VFFS) with In-line ZipperTWN-Z ⁄ TWN-ZH

Features

These vertical form fill seal machines have a built in zipper device.

The zipper device control box is integrated with VFFS machine that improves its maintenance ability.

Specifications

| Bag Size Range | Bag Width | 80 - 250mm (Converts for filling flat bags) |

|---|---|---|

| Bag Length | 100 - 410mm | |

| Packaging Speed | TWN-Z : Max. 50bpm | |

| TWN-ZH : Max. 65bpm | ||

| Machine Dimensions | W 1850 x D 2470 x H 1600 mm | |

| Machine Weight | Approx. 1300 kg | |

OPTIONS

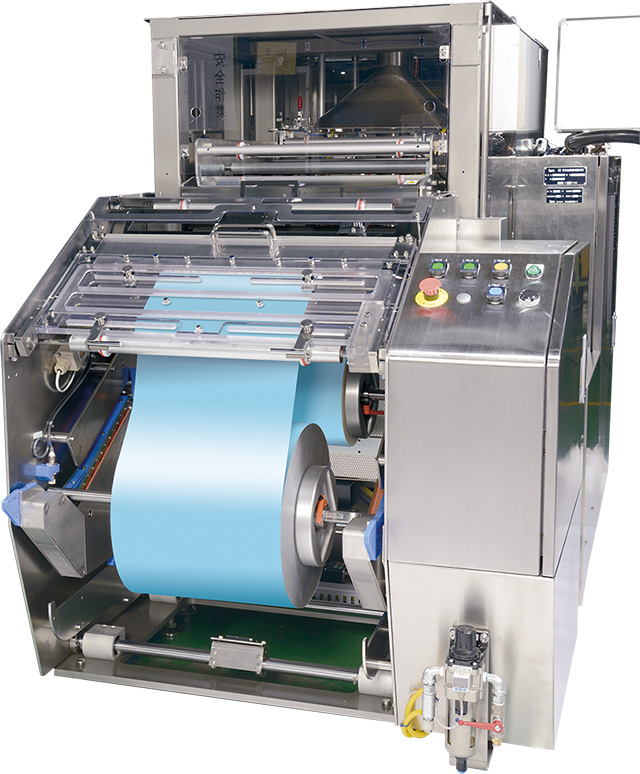

Automatic Splicer

Automatic film splice can be done without stopping machine.

Other options

- Printers

- Automatic printer positioner ⁄ adjuster

- Print inspection ⁄ monitoring device

- Automatic tracking correction

- Static eliminator

- N2 gas filling

- Chain-bag header

- I(V)notch

- Punch hole

- Gusset bags ⁄ Block-bottom bags ⁄ Wide-top bags ⁄ pleating

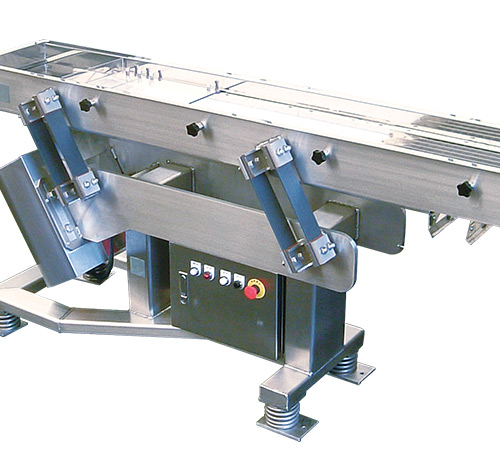

- Various types of vibrators

Related Products