Case study of VFFS packaging "Bean Sprout"

March 13,2023

VFFS machine is able to pack various kinds of product. It is common to be used for the secondary packaging such as candy bag, chocolate, or for the product already packed in the individual package. VFFS machine also be used as primary packaging for the product with characteristics which have to be paid attention. We are going to share the case of such product in the view of machine introduction and how to decide the specification.

■ Packaging Beansprout

Beansprout is a food eaten widely in East Asia and Southeast Asia. It is cultivated by soaking mung beans or soy beans in water and grows in dark room without sunlight.

It is a popular food in Japan and easy to buy in any supermarket.

Due to the characteristic of growth, the production process from the growth to the packing is totally controlled in factory. For packaging the grown beansprout, VFFS machine is used. Bean sprouts are a mass-produced product. The factory is generally 24 hours full operation including the VFFS packaging machine.

■ Specification of VFFS machine

As the growth of beansprout needs a lot of water, the humidity of the production site is quite high, which means the production equipment needs to be durable for humidity. Among the equipment, especially the combination weigher uses water when washing down, it has to be water resistance.

The shape of the beansprout is long and thin. It is easy to be bent.

However, the mass-produced beansprout needs to be packed and delivered in the condition to remove as much the air in the package as possible to reduce the transportation cost.

Considering the nature of the beansprout and the condition of moisture make the machine specification complicated. The machine in standard specification will not able to handle, there would be no production efficiency, also the maintenance is hard. In TAM, we have taken various measurements for handling beansprout.

■ Machine configuration

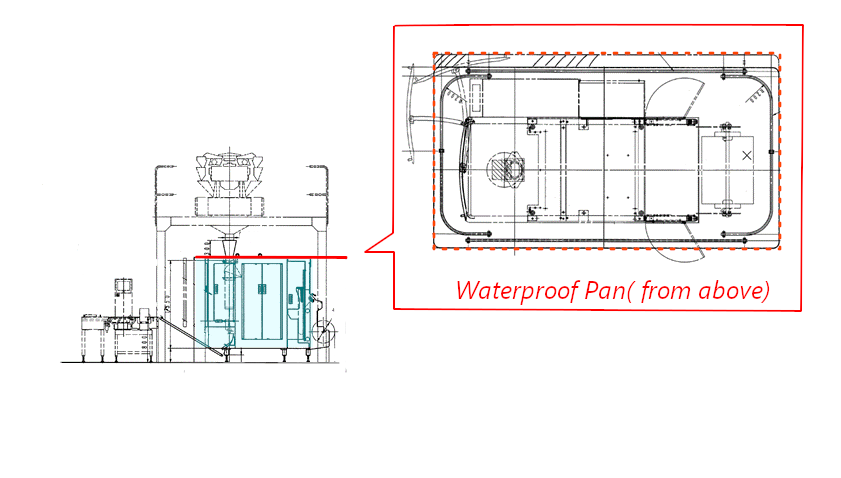

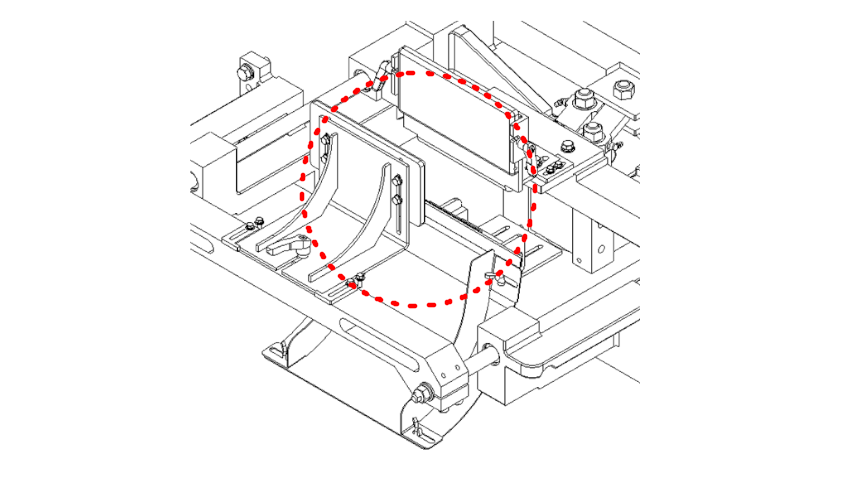

Stainless steel for main frame considering the production environment. A waterproof pan has installed to prevent the water drop from the above-installed weigher.

A curtain rail has been mounted around the outer circumference of the waterproof pan that prevents water drops bouncing when cleaning the floor.

■ Protection from the damage

The damage on beansprout is mostly due to bend. The bend tends to occur when the force is applied in length direction.

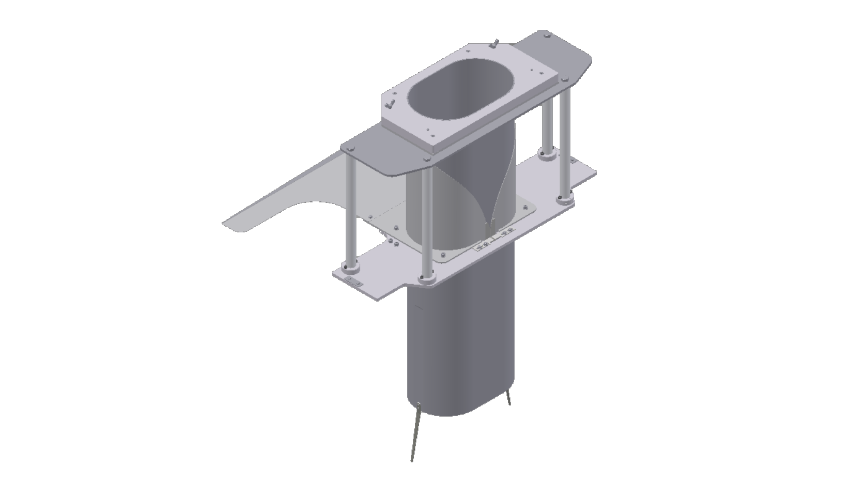

We have examined the various options to improve the receiving posture of the beansprout that is dropped vertically. Normally, the unit where the product and film pass through via the bag forming unit is round-shaped tube. We changed the shape of the unit so as to the posture of the beansprout become in parallel as much as possible.

■ Air extraction

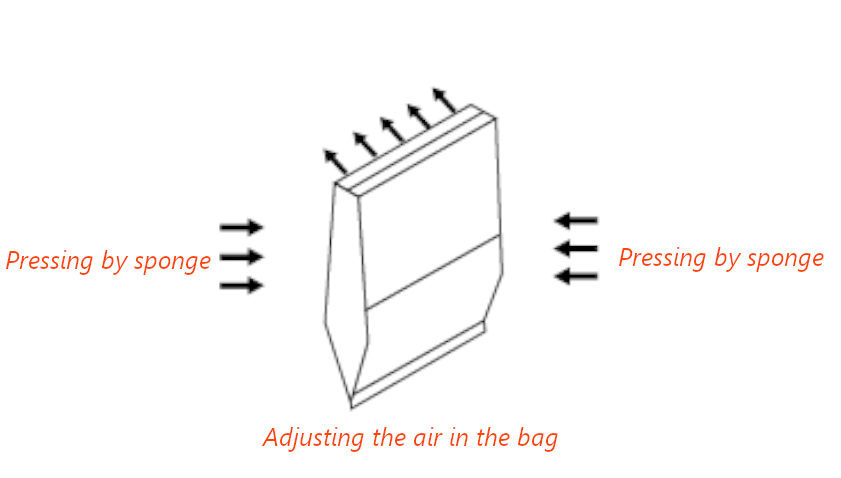

As described, beansprout is mass-produced vegetable in the factory. To keep the freshness of beansprout, it is necessary to transport the large quantities at one time.

The point to be focused is “how many packages can be packed in cardboard case or plastic case? “. So the package of beansprout need to be space-saving, i.e.- the air in the package should be let it out as much as possible.

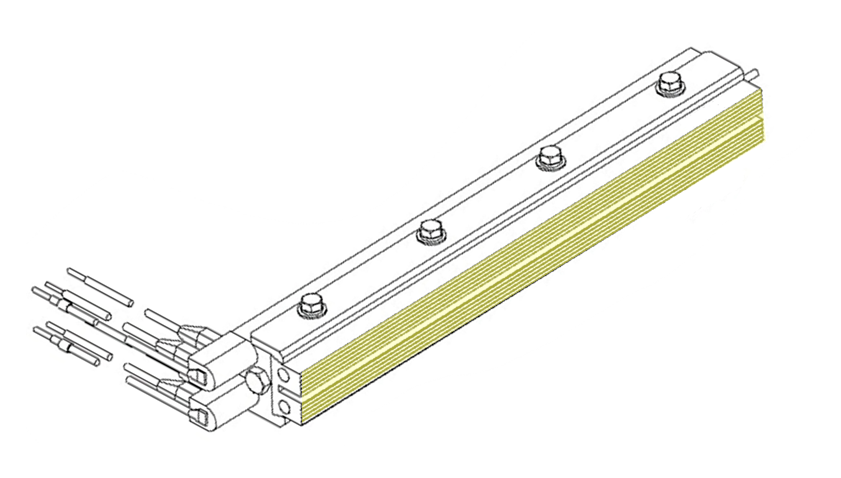

In order to extract the air from the package, we have developed the unit that is driven separately with the end-sealing unit. Moreover, thanks to the sponge part as contact part to press the package from outside, the maximized effect has been obtained.

■ Heater shape

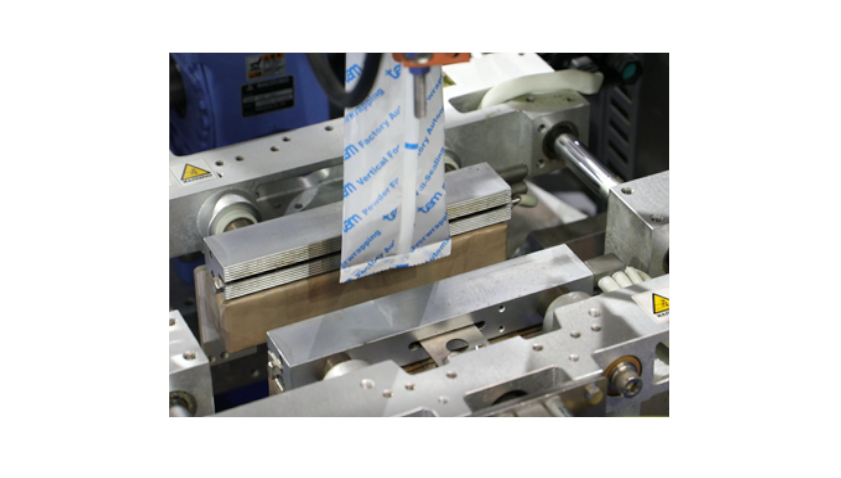

The film used for this specification is with the layer thickness 20-25μm. The weakness of the thin film is to tear when the pressing is too strong.

TAM VFFS machines “TW Series” have the function to observe and control the heater temperature, sealing time and pressure by numerically.

In addition to the standard function, the heater pattern also developed in order to achieve the proper pressure for this case.

The heater pattern is normally several straight lines aligned in parallel. We changed the heating lines wider to give less pressure by the heater jaw, which is too much for the normal products. But this case, with this heater pattern achieved the seal-secured and high-quality package.

■ On determination the specification

For determination the specification, what we did is to know as much as possible the current problem that the customer had had. They already used the packaging machine but they have some problems. We listened and examined that “What can make the situation better?” and then suggested our first proposal. We also checked the production site over and over, and found that “What”, “Why” and “How” the problem had been occurred in various aspects. For example, we checked the each situation of the product item (Sprout types, variation of the package weight) or the situation when film was changed, or when the production started, when the production was almost finished, etc. By carrying out thorough discussions, and hearing the customer’s opinion as specialist as well, the project was determined to adopt TAM VFFS machine as the result of the fully examined proposal.

■ Know-hows and Ideas

There are so many products sold in the market in the world and many kinds of packaging styles to fit with each product. Off course the machine is designed for the requested packaging style. The most important thing is “The machine model is ok, but If the specification is right with the product?” The VFFS machine can pack various products such as snack, candy, flour, fresh food, frozen food, medical product and industrial product etc. But the necessary functions are different in each product. How the specification to be decided? We think that is the know-how and ideas. Tam has been experienced the know-how by not only the technology of VFFS machine but other packaging machine and combine with the new ideas and new technology for always the best proposition.

Tam Contact to: tam-overseas@tam-tokyo.co.jp