The types and functions of VFFS machine(Pillow pack machine)

February 7, 2022

In the modern world, self-service selling such as supermarkets or convenience stores is the mainstream of selling style. Then what required for the package is not only protection of the goods but it plays roles of product information, convenience of carriage and attractive appearance of the goods image. The package is a part of goods, thus, the packaging machine is something you should pay attention for both the high productivity and high quality.

The typical packaging machine for food products is pillow pack machine (or called flow pack machine). The pillow pack machine is the packaging machine to feed film material from a roll, form the film into tube shape, then seal the back and bottom of the tube, and fill the goods material, seal the top, then finally cut the tube and complete as a bag.

The pillow pack machine (flow pack machine) has two types of vertical and horizontal. It is called VFFS (Vertical Form Fill Seal) machine and HFFS(Horizontal Form Fill Seal) machine. This article introduces the TAM manufactured-VFFS machine (Vertical Form Fill Seal machine) about the features, functions, difference of intermittent or continuous mode, and points to be paid attention when you select machine.

What is VFFS(Vertical Form Fill Seal) machine ?

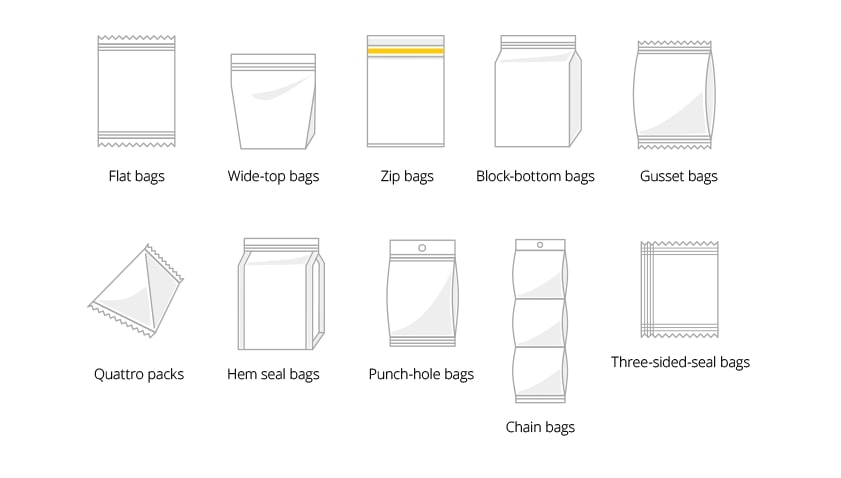

VFFS machine is a wrapping machine to form film in tube shape that is continuously fed from film roll to make bag (like a pillow shape), then, feed the film tube in vertical direction and fill the product simultaneously. After sealing the bottom of the film tube, then materials are filled in, then top of the bag is sealed and cut, and now a complete bag is discharged from the machine and passed to the next step. In VFFS machine, the bag width and length can be changed according to the product amount or shapes. There are variety of bag styles such as standard pillow bag, gusset bag, square bottom bag, zipper bag, and 3-sided seal bag,etc.

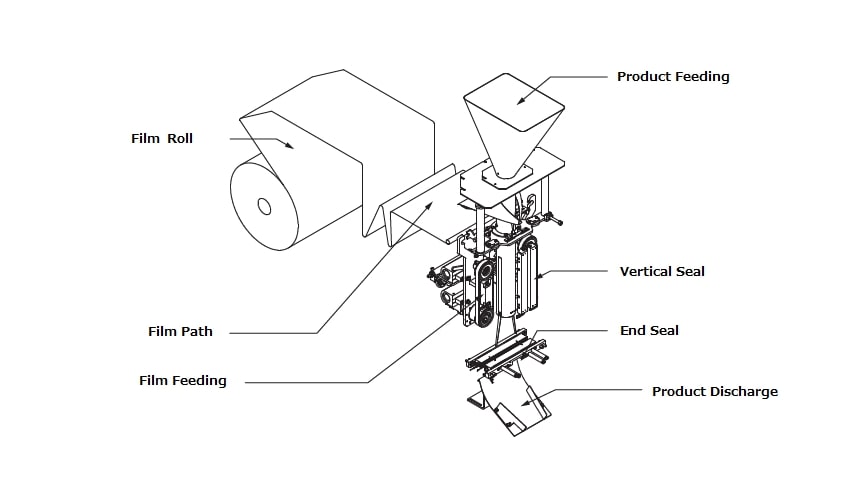

The following image is the packaging process of the VFFS machine.

- Feed the necessary length of film by film feeding motion

- Form the film into a tube and seal the back seal at long seal section

- Seal the bottom of the tube and form a bag

- Fill the product material from product feeder into a bag

- Seal the top of the bag and cut the film

- Discharge the complete bag at discharge section

Types of VFFS machine

VFFS machine has mechanism of intermittent or continuous. The intermittent type has a stop motion during a film feeding pitch. During the stop motion, the bottom and top seal is made by the end seal unit, which is fixed its position.

The continuous type has no stop motion and feeds film continuously. Unlike the intermittent type, the end seal unit moves up and down by following to the film feeding motion when end sealing is acted. The up and down movement prevents the product from damage that might be occurred by dropping.

Therefore, the continuous type is chosen for the case of high speed operation, for fragile and delicate products while the intermittent type is adopted for the products which do not have much worry to get damaged by fall and not required for high speed operation.

The purpose of VFFS machine

VFFS machine is suitable in case you want to wrap a certain amount of product in a bag. For example of using VFFS machine, the product such as solid products, powder products or granule products.

Due to the structure that VFFS machine wraps the product by dropping the product into bag, so, deformable or delicate products are not best suit for VFFS machine.

Products can be wrapped by VFFS machine

- Sweets and snacks: Snacks, Chocolates, Baked sweets, Candy, Cookies, Marshmallow, Rusk, Nuts etc.

- Powder products: Seasoning, Spices, Soup powder, Bread crumb, Cocoa, Coffee powder, Milk powder, etc.

- Row noodle, dry noodle: Udon, Buckwheat noodle, Spaghetti etc.

- Frozen products: Frozen meatball, Frozen chicken nugget, Frozen pilaf, Frozen vegetables, Frozen dumpling etc.

- Vegetables and beans: Green pepper, Bean sprouts, Cut vegetables, Soy beans, red beans etc.

- Prepared food: Sausage, Cheese, Fish sausage

- Others: Desiccant, Insect repellent, Agrichemical, etc.

The above products are just the examples that VFFS machine is suitable to wrap, there are many other kinds of product can be wrapped. The type of the VFFS machine may differ depending on the products. Tam can offer best suit model of our VFFS machine according to the customer’s product and its purpose.

Functions and Options of VFFS machine

For each product to be wrapped the proper VFFS machine should have proper specification and functions. The followings are the some of the important functions and options when selecting the proper VFFS machine.

Gusset block-bottom device

Gusset block-bottom device has a function to have gussets at the both side of bag. This device is used in case the filling amount in a bag is relatively large or standing bag style is produced. Standing bag is produced by folding down the bottom flaps of the bag underneath the bag bottom to make the bag bottom in flat.

Punch-hole device

This is a device to punch a hole on top of the bag for the purpose when the product is displayed on hook in shop.

I-notch / V-notch device

This is a device to notch the bag for opening the bag easily. According to the notch shape, it is called I-notch or V-notch.

Registration mark sensor

Registration mark sensor is to read marks which are printed on the film to detect correct film length of one bag. With this function, the film can be cut at the right position of the print pattern.

Zipper device

Zipper bag is produced by attaching a zipper at the top opening of the bag to re-open. Since the zipper is attached in a process of feeding film roll, the film cost is less expensive than the pre-made bag with zipper.

N2 gas filling device

This is a device to fill N2 gas in bag to replace oxygen into nitrogen for the purpose of antioxidant. N2 gas filling device is used for the products such as snacks, nuts and coffee etc.

Automatic Splicer

Automatic splicer is a device to connect film roll automatically without stopping machine. When the film roll in operation is terminated, the roll is connected to the next roll automatically. This is more accurate than changing the roll by human and the time for changing work can be saved.

Points to be noted for introducing VFFS machine

The following points should be considered for introducing VFFS machine in case of machine trouble, or to obtain better support suitable for your product and production site.

Support or aftersales care after introduction

Depending of the business distribution, the machine is directly sent to the place and the purchaser has to install the machine to the site and set up for operation by their own. In order to handle the machine without problem, it is a crucial point to confirm if necessary support or aftercare will be provided for installation and after installation.

Compatibility with the product and production site

Each VFFS machine model has difference in machine size, output, and the bag size and style the machine accommodate for. Depending of the necessary option devices or connection to the before/after process, the required space should be changed. Therefore, when choosing VFFS machine, be sure the model is suitable for the product and production site if enough space can be secured for introduction as well as the machine fulfill the required specification for the product.

Proven-experiences

When considering introducing VFFS machine, it is desirable to choose the manufacturer or distributor who have proven experiences for making use of machine with a sense of security. It is more likely to receive suitable suggestion for your production site, and necessary support based on their experiences and knowhow if the manufacturer has proven experiences.

Features of TAM VFFS machines

Tokyo Automatic Machinery Works, ltd. (TAM) has started the manufacturing and selling VFFS machine in 1963 and we have almost 60 years of experiences and know-how. Tam have wide variety of VFFS machine models includes short-drop model which shorten the drop distance for reducing damage on the products, zipper model to add zipper on the bag, supersonic seal model, and other suitable models that meet to the customer’s needs.

Many of TAM VFFS machines won the Japan Pack Award held by Japan Packaging Machinery Manufacturers Association. We provide our VFFS machine with great efficiency, high security and high quality. We also provide technical support for machine trouble or operation inquiry by telephone, email, instruction in web and web meeting. Our close network with distributers in overseas will support the customer in overseas quickly even in case of emergency.

TAM VFFS machine can handle wide variety of products: the solid products such as snacks, chocolates, candies, powder product s such as coffee, cocoa, powder milk, starch, frozen foods, frozen vegetables, and medical powder products such as barium, animal antibiotic, etc.

Many kinds of bag styles are available, including flat bags, gusset bags, three-sided seal bags, and triangular pyramid ‘Quattro packs’. The field Tam is good at is the high value-added packages which are zipper bag that can be close and re open, bag with a valve to releases the gas from a bag such as coffee and ultrasonic sealing etc.

Among them, the wide-top bag is our original bag style that has been improved the easiness of taking the contents out of bag as well as having an effect of good appearance on display by self-standing. Wide-top bag has excellent convenience due to the wide opening in comparison to the conventional gusset bottom bag

Not only this, TAM can offer new bag style that capable to be opened transversely without interfering the long seal.

Tam Contact to: tam-overseas@tam-tokyo.co.jp