Commitment to Quality

To Provide machines that satisfy customers, we put our efforts on process management and quality management for our manufacturing process from parts processing, frame manufacturing, assembling and final completion. We have designing team and factory and service departsment in the same premise that enable fast and collaborative support to respond the customer's request.We have acquired the quality management system ISO9001.

Packaging test

Confectionery & Gift Wrapping Machine

Vertical Form Fill Seal Machine

Auger Filling Machine/VFFS Machine

Solutions / Industry

Packaging of coffee product

Inflation of bag

Coffee bean emits carbon dioxide gas even after roasting and filling into package.When the package is filled and sealed, the inner pressure rises and sealed package could inflate and burst.Therefore, the carbon dioxide gas from the coffee bean should be released out of package through a valve.

Keeping freshness ( Measurement for oxidization)

Coffee contains oil, that gives rich aroma flavour. Since the oil get oxydized when the oil is exposed to the air, so it is important to fill nitrogen gas in the package to get rid of oxygen to keep the fresh flavour.

Select the proper valve for gas releasing

By pasting a valve on or inside the package, the gas generating from coffee is released out the package, accordingly the package inflation and burst is prevented.The valve doesn’t allow inflow from out of package which keeps the coffee fresh.”Inner valve” is used by pasting inner side of film and “Outer valve” is used by pasting on outside the film.Which valve type to be selected depends on the usage; the inner valve is superior in gas releasing function, and the outer valve is relatively reasonable price.

Packaging frozen fish

What is so called frozen food is the food which is kept and treated in minus 18 degrees Celsius from throughout the process of production, distribution and retailer to the consumers. The points to pay attention in the condition of low temperature are as follows ;

Measurement for low temperature condition

The electrical parts those are not suitable for low temperature need to warm up to keep constant temperature.When dew condensation is generated inside the packaging machin due to temperature difference, it may cause machine malfunction or failure.

Measurement for film breakage

Most of frozen food is hard and could occur pin-hole when they are dropped in the film bag.It is necessary to have the mechanism for machine to reduce the impact .

Zipper bag Packaging

VFFS package with zipper

Various food products such as cocoa, cereals, candies, chips and sausages are packed in VFFS Zipper bag. Adopting the re-open and re-close bag style increased the level of convenience and reduced the film material cost.

Re-closing

The zipper re-closing function increases the convenience when using. Due to the wide opening, it is easy to take the products out. The consumer can use just the amount they need when they want, and the zipper bag assures the good keeping.

Design

The self-standing gusset bag has better appearance when displayed in stores. The product can be appealed with print design to make use of the flat side of the package.

Wide-top Bag®

The square bottom style can show the package surface flat, so the design printing and the display appearance looks better. It is effective for the appeal in stores. This style is functionally superior that is able to pack larger amount with a small amount of the packaging material comparing to the standing pouch. The zipper re-closing function increases the convenience when using. Thanks to the wide opening of this unique style, it is very easy to put your hand and spoon in the package to take the product out.

Case study

| Product | Type of machine | Model | Speed | Package style | Film material | |

|---|---|---|---|---|---|---|

| Mixed Nuts | VFFS machine | TWJB3R | Pillow bag with punch hole | Laminated film | ||

| Cookies | VFFS machine | TWJB3R | 85bpm | Pillow bag | Laminated film | |

| Ice |

VFFS machine Stainless-steel model |

TWJB3R |

70bmp for 180g 40bpm for 600g |

Pillow bag | Laminated film | |

| Cookies | VFFS machine | TWTT3R | Pillow bag | Laminated film | ||

| Bread | VFFS machine | TWJB3LR | 55bmp*2machines | Block bottom gusset | Aluminium metallized film | |

| Mixed beans | VFFS machine | TWJB3R | 75bpm | Pillow bag | Aluminium metallized film | |

| Frozen dumpling |

VFFS machine Stainless-steel model |

TWJB8R | 55bpm | Pillow bag | Laminated film | |

| Cracker | VFFS machine | TWJC3R | 100 bpm | Gusset bag | Laminated film | |

Distributor / Agency introduction

The machine installation in site, commissioning and maintenance are carried out by trained-engineers in our sales distributor or agent. In some cases TAM engineer work together, but most of the cases they are capable to work alone, so the customer doesn't have to wait the engineer service from Japan.

SELPAK AUTOMATION PTY. LTD

JAY INSTRUMENTS & SYSTEMS PVT. LTD.

Trinox Engineering Services Pte Ltd

SENTA PACK MACHINERY & SERVICE CO., LTD.

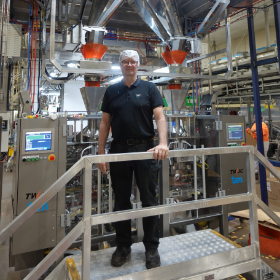

User Interview

with introducing company

Packaging style

Pakcage presentation by VFFS machine

(Pillow chain bag)

Pillow bag (Pillow chain bag)

The most common packaging style shaped like a pillow. This is the basic application of VFFS machine to step up the other packaging style. Perforating in the seal top between the bags produces chain-bag style such as 3 chained bags or 5 chained bags.

Pillow gusset bag

Placing gussets on both sides of the bag to widen the bag. The inflated bag with the contents looks appealing. If the bag width is same with the pillow bag style, the less amount of product can be filled in.

Block bottom gusset bag

Placing gusset on both sides and bottom of the bag to produce standing bag. The standing style has good appearance for display.

Quattro packg

The shape of triangular pyramid has fancy appearance, protective design and suitable for appetizer. Mostly used for small bag. When the small quattro-packs are packed in a bigger bag, it can get a sense of volume.

Zipper bag

Placing gusset on both sides and bottom of the bag to produce standing bag. The standing style has good appearance for display.

3 sided-seal bag

Folding the film in lengthwise and seal the top, bottom and one side to make a bag. There is no layer-point of the long seal and end seal that pillow bag style have, thus, the 3 sided-seal bag is suitable for the products that sealing performance is required such as powder.

Wide-top bag

The top of the bag is flat same as pillow bag, and the bottom flaps are folded so that the bag bottom shapes as square and self-stands.Good appearance in display as it is self-standing. Zipper application is also possible.

Infeeding methods to VFFS machine

Weigher with gantry

Gantry stage is placed on the VFFS machine and mount the weigher on the gantry. This is the most simple style of feeding system. Desirable ceiling height for 5 meters.

Feeding conveyor

Used in factory with low sealing, but wider installation space is needed. Washing device and air blow device to blow off the water and remaining material can be mounted for usage without removing feeding hopper. Feeding by hand is possible depends on the specification.

Weigher on VFFS machine

Weigher is directly installed onto the VFFS machine which can save the space. By placing 5 straight feeder,

on VFFS machine

Auger filling machine on VFFS machine

Auger filling machine is directry mounted on VFFS machine. Passing the auger screw into the former tube to fill directly in the formed bag. Reduce the powder rising , keep the production area clean and less damage on the machine.

Film material for VFFS packaging machine

For packing by VFFS machine, a sheet from the roll film is formed as tube shape and seal at the back seam, the bottom and top is sealed to create bag. To avoid the sealing defective, proper seal temperature need to be set with considering the film material feature. For packaging, there are various kinds of film representing listed below.

Low Density Polyethylene

LDPELow Density Polyethylene

【Feature】

Superiot in water resistance, acid resistance, alkali resistance, impact resistance and heat sealability. On the other hand, it tends to be inferior in organic solvent resistance and heat resistance.

【Application】

Single layer is used for food, Frozen food, Garbage bag, General merchandise etc. Laminated film is used as sealant for confectionery, snack, dry food, liquid etc.

Linear Low Density Polyethylene

L-LDPELinear Low Density Polyethylene

【Feature】

LLDPE is polyethylene with a narrower molecular weight distribution than LDPE due to its processing method. LLDPE has superiority in strength, hot-tack behavior, contaminant sealing performance, impact resistance.

【Application】

Single layer: Generally used in Food and verious kind of merchandice. As sealant for Laminated film, used for heavy weight packaging, liquid packaging( strength, impact resistance), high-speed automatic filling and VFFs filling using gas-flashing(hot tack), past filling and powder filling (contaminant sealing performance).

Cast Polypropylene

CPPCast Polypropylene

【Feature】

LSuperior in moisture resistance and transparancy in comparison to LDPE. Inferior in flexibility and impact resistance to LDPE.

【Application】

Homopolymer as single material, Copolymers obtained by copolymerizing ethylene are used for laminates. Single CPP is used for bread, vegitable, noodle packaging. OPP/CPP or KOP/CPP are used for confectionery.

Oriented Polypropylene

OPPOriented Polypropylene

【Feature】

OPP is created by stretching the CPP. It is tend to be less stretching than CPP, but superior in tensile strength, moisture resistance, and transparancy. OPP-based film have a narrow range in applicable temperature and prone to shrink.

【Application】

In single material, part-coating bag for dry food, or fusion sealing bag are most used as reasonable price bag. As laminated film, OPP/CPP or OPP/PE are widely used for general merchandise, dry food, rice cracker, candy, instant noodle, etc. OPP does not have supriority in gas barrier, it isn't suitable for long-term strage, packing with oxygen scavenger or gas-filled packing.

Polyvinylidene chloride coat OPP

KOPPolyvinylidene chloride coat OPP

【Feature】

KOP is the OPP film coating with Polyvinylidene chloride coat. Superior in moisture resistance, gas barrier, and fragrance retention.

【Application】

Composition such as KOP/CPP or KOP/PE are widely used in dry food with gas-filling, packing with oxygen scavenger and dampproof packing.

Polyethylene terephthalate

PETPolyethylene terephthalate

【Feature】

Superior in cold resistance and heat resistance, suitable for frozen food packing or retort pouch packing. Used for coffee or spice packaging due to the superiority of fregrance retention.

【Application】

PET is used for packaging frozen food, retort pouch, coffee, tea leaf, spice etc, by pasting sealant film. The aluminum evaporated PET film has excellent barrier function and is most commonly used evaporated film for packaging.

Spanbond, Needle punch,

Spunlace, Chemical bond

Non-woven fabric

Spanbond, Needle punch, Spunlace, Chemical bond

【Feature】

Literally, it is a cloth but not woven. The non-woven fabric is made by bonding the fiber to create a sheet of cloth. It has softness, strength, good air permeability and cushionning.

【Application】

Widely used in the dairy use products. Medical mask, filter, wet towel, tea bag, coffee drip bag etc.

Required film function for VFFS machine

Smoothness

If the film doesn’t have smoothness, it causes film jamming, pitch error or the filling contents are not dropped smoothly.

Stability of dimension

If the film is stretchy or uneven for the printing pitch, the packaging loss could be increased or can’ t be used.

Low temperature sealability

If the film have low-temperature sealability, it is easy to set the temperature and can expect high-speed packaing, and decrease of sealing defective incidence.

Hot tack property

Hot tack property is the level of the film peeling right after heat sealing is perfomed. Hot tack property could be an essential condition as the filling content is dropped right after the end-seal is performed. Gas-filling specification also need this function.

Antistatic property

In case the filling content is powder or granuled product, the antistatic film is required.