Packaging machine in relation to parts processing

October 05,2022

Machines have various roles and functions. For examples there are machines for transport vehicles or ships, or machines to assist in household functions such as home appliances. Obviously, the equipment and the composed parts are various kinds according to the usage of the specific machine. Packaging machine is literally a machine for packaging and composed of the distinctive parts that are necessary for automatic packaging.

Parts processing

Part processing has three typical categories. Cutting processing is to drill or make a hole on the metal or plastic parts. Deformation processing is to bent or deform by mold. At last, welding processing is to weld the parts together at heat by using filler metal. In many machines, the parts as the components of the machine are manufactured using the above processing methods according to the application, and the machine is completed by assembling those parts.

Parts processing in relation to Packaging machine

Here is an example of Vertical Form-Fill-Seal machine. (See the detailed information of VFFS machine from here)

https://www.tam-tokyo.co.jp/english/blog/articles/220207_vffs-machine/

For forming bag from a sheet of film that is supplied from a film roll, the critical part is composed by a former and tube. In order to fulfill the function of the important role, various processing methods are used.

■ Processing the forming unit

The critical point of the forming unit is to weld the characteristic streamline-shaped parts. We have detailed instructions by drawing including the welding angles of each combining parts. Since the forming unit is such part the film touches and passes through the surface, the surface has to be finished in smooth and the filler metal is taken off to prevent scar. The forming unit is a most important part for the film forming process in the VFFS machine. The skilled engineers specialized expertise work on the parts processing in TAM.

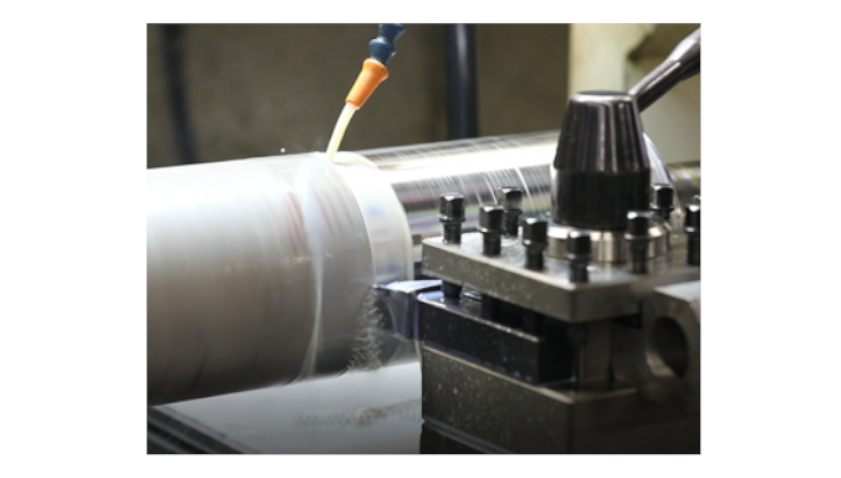

■ Processing the forming tube

As the tube is the parts the film passes on, its surface is needed to be finished by strict instruction with high accuracy. The tube diameter is required the accuracy in 1/1000mm since this is the important factor for the bag width the forming tube make. The method in this process is cutting, and the lathe turning machine is used. Not only the proper selection of the cutting tools is required, but also the control to prevent deflection of the tube is important. This is the depth of the parts processing and the know-how the manufacturer is asked for.

■ Processing the frame

The frame is composed of welded angular pipes. The machining center processes on the frame such as taps, drilling h7 holes and drain holes, etc..

What we have to pay attention when processing frames is distortion.

How to fix the frame on the pallet to prevent distortion is the experienced skill and know-how the manufacturer has.

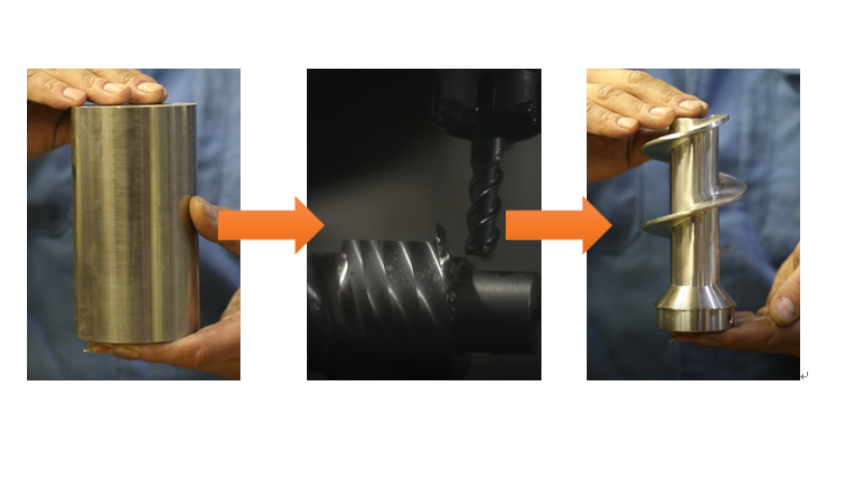

■ Processing auger shaft

This is the most challenging parts in this article. The auger shaft is processed from a cylindrical shaped material to make a spiral-shaped part by applying a tool, and both the material and the tool rotate while processing.

The possible tool is the ‘combined processing machine’ by integrating lathe and milling machine, which are the typical tool of the cutting processing. All the motions are programed by the combined processing machine.

Such an important matter is the surface tolerance because the role of the auger shaft is to fill powder, so it touches the product directly. From the viewpoint of filling accuracy, it is required 1/1000mm accuracy for the outer diameter and the blade shapes.

Therefore, the managing personnel who choose those tools or set the machining is required high-level programming skill and only who mastered are able to be engaged for processing and operating the machining.

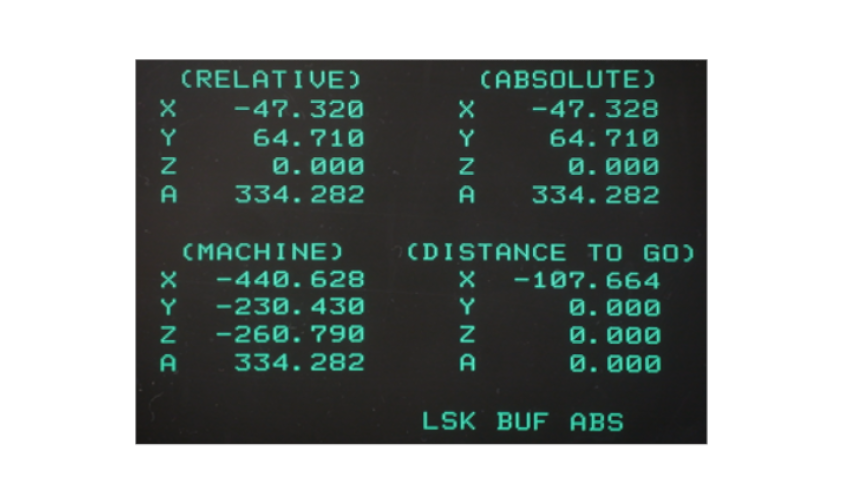

■ Manufacturing management of parts processing

For preparation of the parts processing, each and all steps should be well controlled by manufacturing management team; starting from the material preparation, milling the top/bottom surface, processing the lateral surface, taps and holes from above, taps from the side surface, chamfer the corners, etc.

In the NC processing machine, as the manufacturing is programmable, how to build the program will effect on the “speed, quality and price”.

After receiving the processing drawing is released from the designing team, if the accuracy and the finish of parts processing comes out well, then consequently the assembling and adjustment time can be reduced, and eventually the machine completion in high quality will be delivered to the customer which would be contribution to the operation of the production.

After the drawings for parts processing are released from designing team to the factory,

History of TAM and parts processing

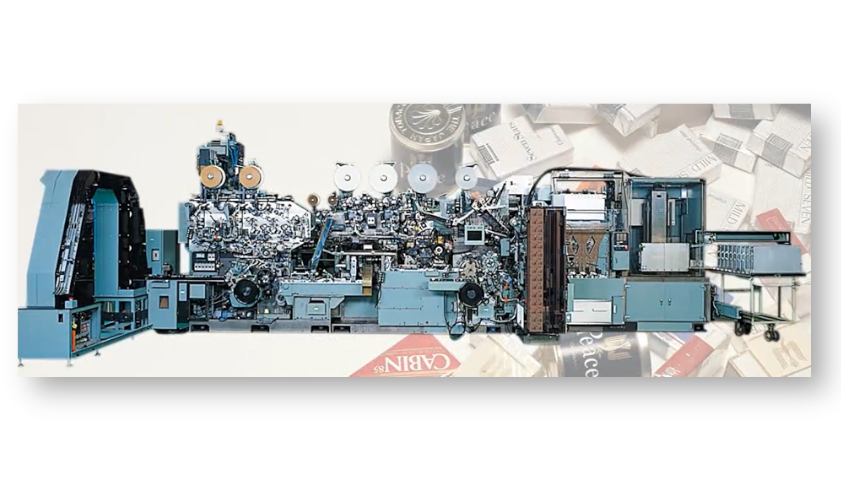

Our history has started from designing and manufacturing the tobacco machinery which has achieved high-speed wrapping attributed by assembling high precision parts.

From long before we have manufactured various difficult parts which require high precision in our own processing department where the many skilled engineers engage.

The model P52/W322 launched in 1971 was the high-speed model that achieves 500 boxes per minute to tailor the tobacco requirement at the time. The package is so called as “soft pack” and the machine collects 20 pcs of cigarettes, wrap the collected cigarettes in aluminum paper, then wrap in the outer wrapping material and finally wrap in film. The machine was required in speed and stable running, therefore the composing parts of this machine are processed in stricter standard than the general industrial standard. Since the electric control had not developed at that time, the mechanical link method was adopted for the machine structure.

There were many irregular parts had been used in each unit for the mechanical link structure, this P52/W322 was such a model with many high-accuracy parts. This model had developed and completed by our technical capability of parts processing that TAM put our efforts and this have affected on our later packaging machine for food or pharmaceutical industries.

From the point of view of packaging

This article focuses on the machine inside, and it may be a bit maniac.

But a machine is composed by many individual parts. One of the crucial things for packaging is the product protection, so the package quality varies if the parts accuracy is not appropriate.

The machine made up with precisely processed parts will produce good quality package, stand with high-speed running, will last longer, and contribute the customer’s productivity. The packaging machines of TAM achieve it and can be used with a sense of such assurance. This is nothing but owing the qualified parts processing. We hope that you consider the machine from such a point of view once

Tam Contact to: tam-overseas@tam-tokyo.co.jp