TAM’s approach to the Frozen food packaging

May 11,2022

As the demands of frozen foods have been increasing along with the changes of the time and our lifestyles, it is indispensable both in ordinary household or food service industry. Tam plays a role for packaging the frozen food. In order to package frozen food, the special attentions need to be payed to the product inside and packaging environment. Tam have offered and supplied the various solutions based on our experiences and history.

Type of machine suitable for frozen food packaging

When you say wrapping machine in one kind, but there are many kinds of wrapping machine. What we introduce here are two types of the forming automatic wrapping machine which forms the bag from film roll to pack the products. One is the horizontal form fill seal machine, and the other is the vertical form fill seal machine that TAM manufactures. The differences are explained below and suitable frozen products each machine can handle.

Horizontal Form Fill Seal Machine

Horizontal Form Fill Seal Machine is a wrapping machine to transfer the product horizontally on the conveyor and wrap the products. The product can be packed in stable position, so the products that is easy to lose the shape or products in tray or plate is suitable to pack by this type of machine. Example: Plate meals (TV dinner), products in tray (Salisbury steak, meat loaf, spaghetti, etc)

Vertical Form Fill Seal Machine

Vertical Form Fill Seal Machine is a wrapping machine to load the product vertically from the hopper on top of the machine and pack in the bag in free fall. The wrapping speed is subject to the product nature. The suitable products are small solid products such as snacks or candies although it will not suit if the product is vulnerable with the fall impact.

Tam can implement the test wrapping in our test room with the customer-provided products.

Example: fried rice, mix vegetables, seafood mix(squid, prawn, clam, etc.) , cut vegetables

In this article, we introduce our cases and solutions for frozen foods that we have experienced with our Vertical Form Fill Seal machines.

Issues to be addressed for Frozen food products from the perspective of VFFS machine

1. Breakage of the product and pin-hole

When the product shaped like fried chickens or meatballs are frozen, they become as hard as stones. These products may break or have cracks when they are dropped for supplying to the wrapping machine as VFFS machine fills the products by free fall. This may generate a pin hole on the film material when filling hard material but not only frozen products. The bag with pin hole can ‘t keep the bag sealed status and may result the deterioration of the quality or contamination of foreign material.

For such issues that could happen with the frozen products, Tam offers the following solutions.

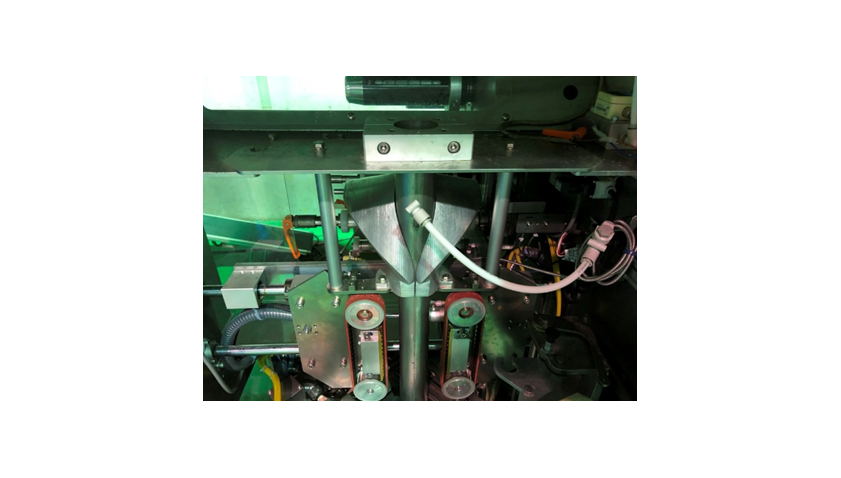

●The beak shaped spreader

The beak shaped spreader is the device to mount at the end of the tube that products pass through when filling. The dropped products are temporary received with the spreader. The spreader opens in the timing when the film material is fed so that the dropping impact is reduced, and the damage on the product and the bag is less damaged.

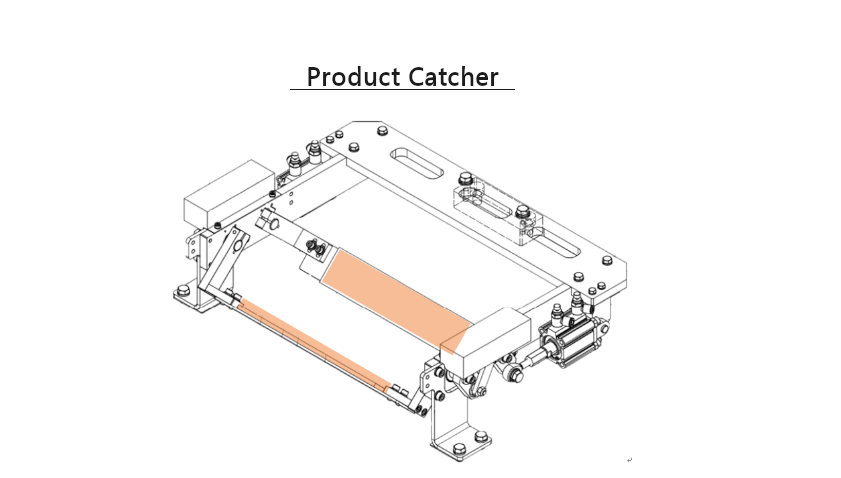

●Product Catcher

The product catcher is the device to mount on top of the end-seal device. The principal function is as same as the beak shaped spreader however, the product catcher is more effective for the small product such as rice or grain since the product catcher can hold the product with the whole width of the end seal.

2. Dew condensation, rust, and cleaning

In the customer’s frozen food production site, there is a concern of the rust generated by dew condensation on the mechanical metal parts due to the temperature difference between the product temperature and the air. The rust may be contaminated in the product and affects on the machine durability. The Daily Cleaning is the fundamental for the food manufacturing equipment. Tam offers the following solutions for the cleanability.

●SUS parts, SUS cover and SUS frame

TAM offers our VFFS machine designed with using SUS material to take measures to the dew condensation and moisture. It is possible to use the SUS material partially depends on the budget or as the measurement for concerning spot.

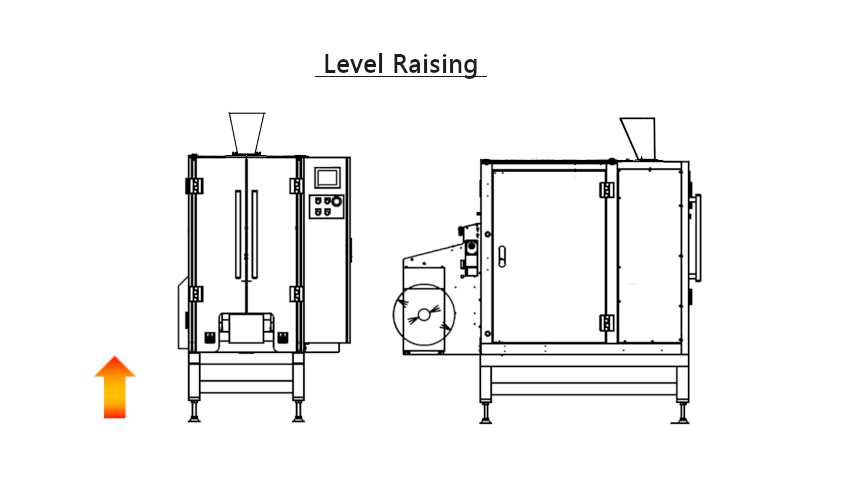

● Level Raising

By raising the machine body, it becomes easier to access to the floor under the machine for cleaning. Mounting the above-mentioned SUS cover on the machine bottom face is also a measurement for the water splashing.

● Compatible machine for 24 hours production

The temperature of the sealing unit and some of the electrical parts are increased while the machine is in operation. Repeating the machine on-off occurs the dew condensation since the temperature of the production site is low. Therefore, TAM recommends the machine to be powered on 24 hours for the usage for the frozen foods and our machine is accommodate with it.

3. Air

When the end-sealing is performed, there will be air packed in the bag too. This increases the volume unnecessary, and the bags can not be cased in the post-process cardboard caser. Furthermore, the space in the bag may be a cause of oxidation and dew condensation. For these problem about the air, Tam offers the following measurements.

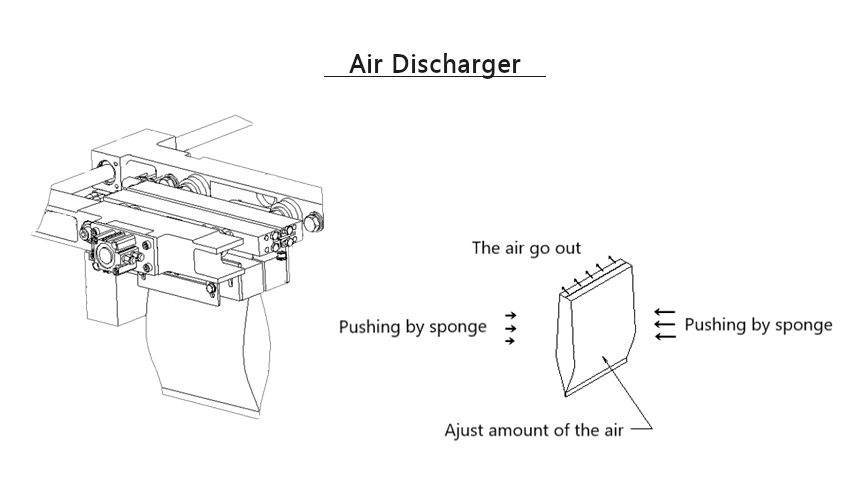

● Air discharger

The air discharger is the device to install the bottom of the end-seal unit. The air discharger pushes the bag from both sides when the end-seal block is closed so that the air inside the bag comes out and bag can keep the proper bag size and proper air volume. This device is often used for rice (fried rice) products.

● N2 Gas Flushing Device

By injecting nitrogen gas while bag is forming, the oxygen concentration inside the bag is reduced to protect the product from oxidation. The amount of the nitrogen gas can be adjusted via touch-panel.

● Double tube

The products pass through the tube when it is fed. Normally, the tube inside become cold by the temperature of the frozen food and there will be dew condensation due to the temperature differences between the inside tube and outside air. For the solution, Tam offers the double tube when the product is low temperature. The double tubes allow a layer of space between the outside air so as to suppress the temperature differences from tube inside, and prevent occurrence of dew condensation.

As mentioned in the introduction, there are more tasks for the packaging frozen food than the ordinary food products which are generated because the product temperature is low. If you have problem with the packaging frozen food, let us support with our assured experiences by our long history.

Contact to: tam-overseas@tam-tokyo.co.jp