Package for Coffee products

March 23, 2022

Let us share about the relations between coffee products and packaging. The most of the packages you see at the coffee shops or supermarkets are made by Vertical Form-Fill- Sealing machine (Called as VFFS machine). The contents of these coffee product are roughly calcified as three types : 1. Roasted coffee beans, 2. Ground roasted coffee(Regular coffee) and 3. Powder coffee(Instant coffee). These products are packed by VFFS machine with innovative techniques that is to be explained later. TAM has experienced more than 170 machines for coffee products since we first delivered the machine to the Japanese coffee manufacturer in 1980.

The coffee beans are in general cultivated within the area of the coffee belt between the north latitude 25 degrees and south latitude 25 degrees. The red fruit called coffee cherry turns to green bean when it is purified. The green beans are then thrashed, selected and through the several times of cup-test by professional, then the beans are shipped to the place of destination. Once the green beans are transported to the manufacturing factory, they are selected again and roasted by machine. The acid and bitterness vary depending on the roasting time, and the taste is determined by how to grind roasted coffee beans. The matter at this point is that the roasted bean generates carbon dioxide gas. In the process of roasting, by the chemical reaction carbon dioxide is accumulated inside the bean. The accumulated carbon dioxide spends time to be released as carbon dioxide gas. As the carbon dioxide gas continues to be released even after the beans are packed, the normal package expands with the gas and then it may be burst. ‘Valve’ is the solution for the problem to release the gas which is adhered onto or inside the package. The bean with carbon dioxide is a token of freshness. The important matter is how we manage packaging with keeping the freshness with proper amount of the gas inside the beans. That is the one of the techniques that VFFS machine can do with the coffee packaging.

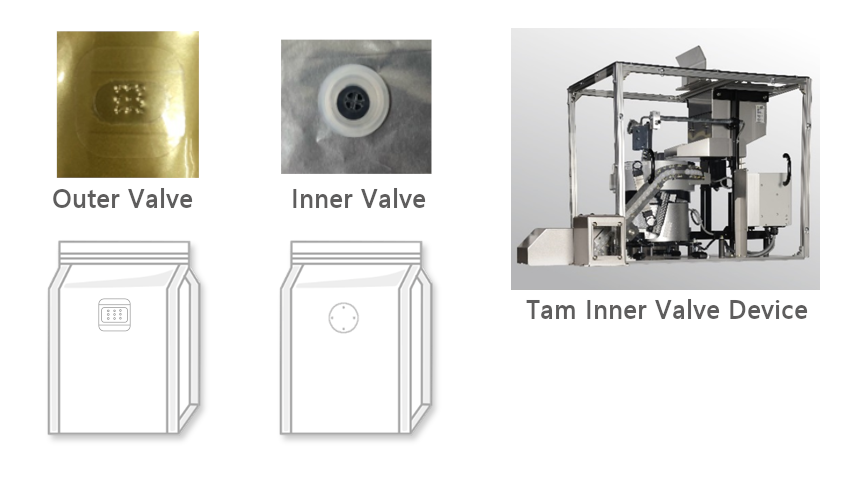

Inner Valve, Outer Valve

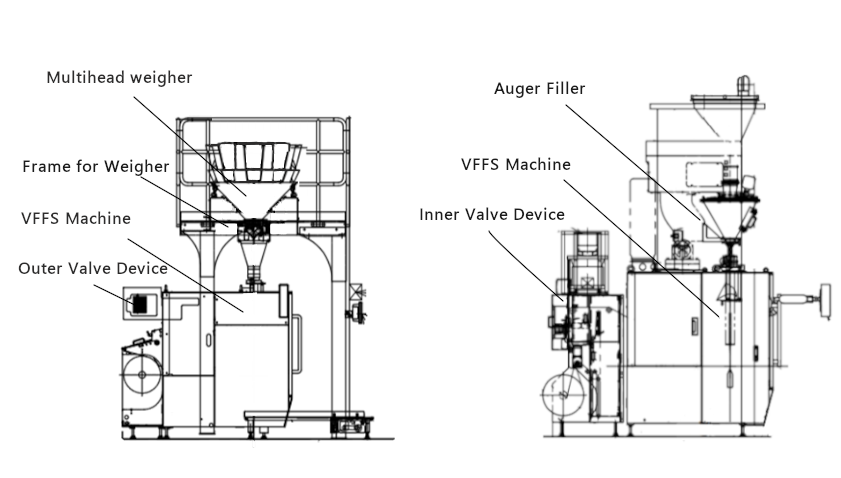

The role of the valve is releasing a certain amount of gas out of the bag when the inner pressure is increased by the carbon dioxide gas. That will maintain the bag with proper packaging shape without explosion. There are two types of the valves; the one is Outer Valve that is attached onto the bag, and the other is Inner Valve that is pasted inside the bag. The Outer valve has advantage in cost. The Inner Valve is tending to be used for the ground roasted coffee (regular coffee) since the powder stuck with the valve is less likely to happen with the inner valve structurally. The VFFS (Vertical Form-Fill-Sealing) Machines that Tam manufactures can equip the valve adhering device in the process of transferring the film from the roll to the forming unit.

Relation between coffee product and weighing machine

In order to control the consistent weight and secure the quality (preventing cracks), it is important to select the proper weighing machine. The followings are the representative weighing methods in coffee packaging.

- Combination scale:

A collective unit of pockets that equipped with load cell. (the number of the pockets can be changed according to the capacity) The each pocket is measured and the ideal combination which is closest to the target weight will be discharged. This is the standard weighing method using with VFFS machine and capable for the products such as coffee beans, grounded roasted coffee, and instant powder coffee. - Turn table :

Using the cups set in a circular shaped unit. The product is filled in the cups, scraped, and weighed just the level of the cup. This has a cost advantage; however there would be a concern of the product cracks. - Trough weighing:

Combination of vibration feeder and load cell. This would suit for the products easily cracked. - Auger Filling (our own manufactured):

For the target weight, the discharge volume is measured by screw rotations. Auger filling machine is suitable for the powder product such as the ground roasted coffee or powder coffee. In the combination with VFFS machine, operation can be handled by single touch panel for both machines.

Bag style with classy appearance

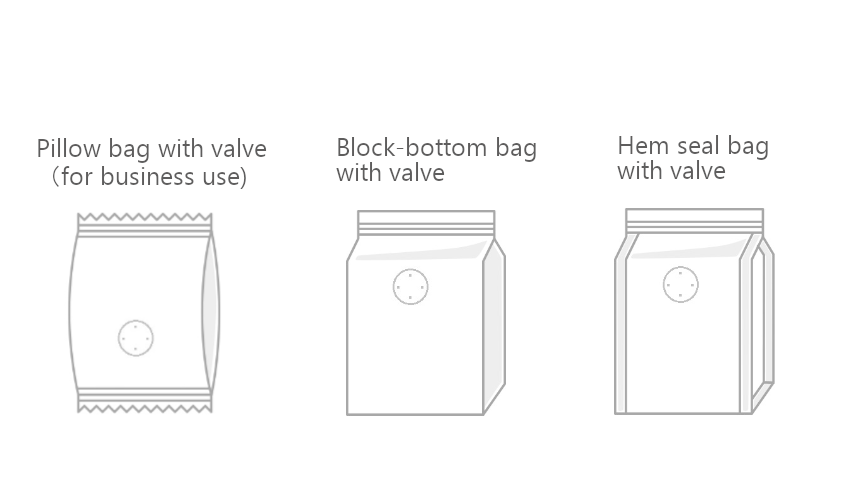

Coffee products are relatively high-value products among the other products to be packaged by VFFS machine. Maintaining the packaging quality is obvious, and many customers pay attention the packaging style as well. The flap bag (pillow bag) is the most chosen when the coffee product is opened and consumed in cafés or shops. TAM-manufactured VFFS machine is capable to special style that has better appearance in display. The block-bottom gusset or hem-seal bags are called as special packaging style.

For making the block-bottom gusset, the bag is formed like a box by square-shaped forming tube and then gusset is formed at the bottom and the top of the bag by tucking with the guide parts so that the bag can stand by its own. The seal on the back(back-seal) called as long seal is created in same way as the normal pillow-type bag. The Hem seal, on the other hand, addition to the above-mentioned processes the four corner edges are sealed, and the long seal is created at one lateral edge so that the bag will have no seal on the back which is more is stylish.

Option devices for coffee packaging

In the above chapters the effectiveness of the valve and specific bag styles are presented. Now, the followings are the option devices for the coffee packaging.

N2 gas filling device

N2 gas filling device is a device to replace oxygen in the bag into nitrogen by filling N2 gas for the purpose of antioxidant. The gas can be stored in the auxiliary chamber. This is important device for keeping freshness of the coffee.

Gusset block-bottom device

Gusset block-bottom device has a function to have gussets at the both side of bag. This device is used in case the filling amount in a bag is relatively large or standing bag style is produced. Standing bag is produced by folding down the bottom flaps of the bag underneath the bag bottom to make the bag bottom in flat.

I-notch / V-notch device

I-notch or V-notch device is a device to cut a notch on the top seal for easy opening. The notch shape can be changed by the knife shape.

Anti-Static Device

Anti-Static Device is to eliminate electrostatic generated on the film by friction. The product may adherence to the film by electrostatic that may cause the product contamination in the seal area. Conducting the electrostatic elimination just before the film is delivered to the end seal section, the product adherence can be prevented so as to the clean seal without contamination.

Things to be confirmed for consideration.

Tam offers suitable packaging machine by using the specification check sheet for better understand the customer’s requirement nevertheless the inquiry is for a new machine, renewal or additional to the existing machine. The check items are:

- Bag dimensions: if the bag width changes then the appropriate size change parts will be needed.

- Bag style: Pillow bag, Pillow-gusset bag, block-bottom gusset bag, hem-sealed bag etc. Depends on the bag style the option device will be needed.

- Product weight: Depends on the weight the option device will be needed.

- Film material: In coffee products, high-barrier aluminum laminated film is often used.

- Wrapping output: number of bags required to produce per min or hour.

- With or without Valve: Necessity of pinhole if valve is not needed.

Please feel free to contact us for an inquiry of the packaging machine.

Tam Contact to: tam-overseas@tam-tokyo.co.jp