Case study of the paper overwrapping machine "Coated paper"

August 7,2023

It is ordinarily familiar in Japan we see many wrapped boxes by wrapping paper that are sold in the department stores or souvenir stores. It is Japan's particular culture and once it got an attention from overseas that the skilled staff at department store wrapped the gift box immediately in the way calls ‘department wrapping style’. Due to this cultural background, we have developed and launched our overwrapping machine ‘AR Series’ that automatically wrap the box in wrapping paper. We have 90% shares in Japanese market and many users across the country.

Recently there are more inquiries from overseas; AR users have spread to Asia and Europe. In the next paragraph we introduce our case study to install the ARZZ1 model overwrapping machine to a confectionery company.

■ AR Series Overwrapping machine

Currently we have mainly two types of AR overwrapping machine model. One is standard ARZZ1/ARZZD1 and the other is ARZZ2/ARZZD2 for bigger box. The model is basically determined by the box size. If the box size is within our standard size range the ARZZ1/ARZZD1 is selected, and if the box size is bigger than the standard range, ARZZ2/ARZZD2 is offered.

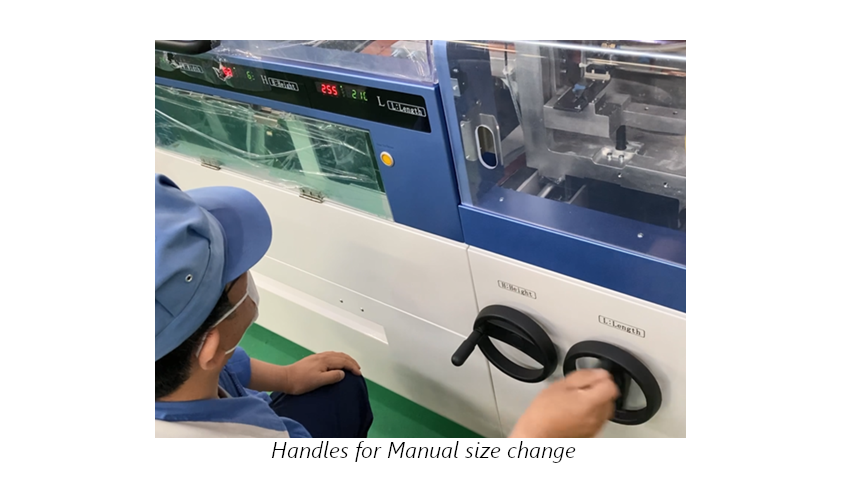

From among them, it is further divided into two types of machines. The model that has the function of ‘Automatic size change’ is called as ARZZD, and the model that has manual size change function is called as ARZZ. In the manual size change machine, the box size change is executed by turning the handles. We usually recommend ARZZ model to the customer who needs to wrap one box size, or 2-3 box sizes.

The ARZZD has automatic size change function and manual handle as well. With the automatic size change function, operator can change the wrapping box size by only selecting the product that has been registered via control panel. To the customer who has many box size or the frequent production lot changeover we recommend them ARZZD model.

■ Case study of the paper overwrapping machine "Coating paper"

The model we have installed in the confectionery company is ARZZ1 since their product size are 3 types and no frequent changeover is necessary in their production.

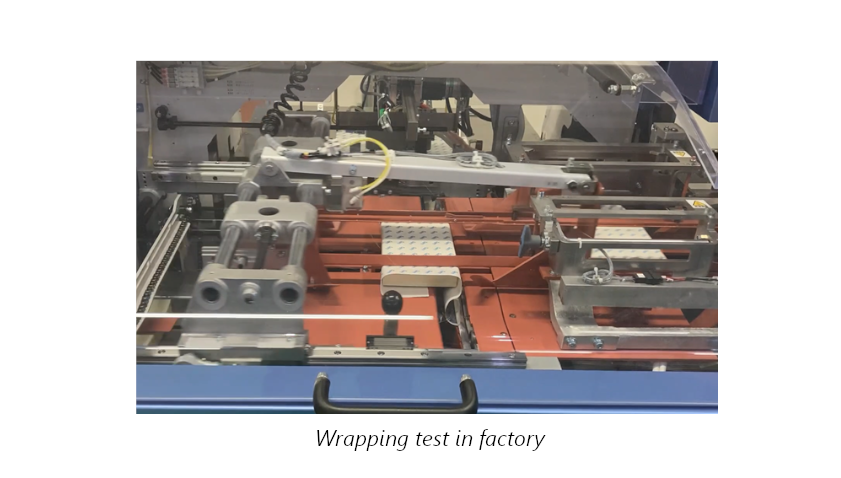

■ Wrapping test and making sample

After determination the suitable model, we made sample package by the machine. Nothing but the actual wrapping sample is much more effective and persuasive than the text and numbers explanation. When we make wrapping sample with the machine, firstly we receive the box sample from the customer. We received empty boxes as sample. The customer didn’t need to send us the inside contents since we put some weight in the box when we wrap them with the machine. We then calculated the wrapping paper size for the box by using the calculation sheet, prepared the wrapping paper and then made the wrapping in the machine.

We sent the wrapping sample to the customer so that they can check and the wrapping quality and then proceed to the next step.

■ Wrapping paper and optional devices

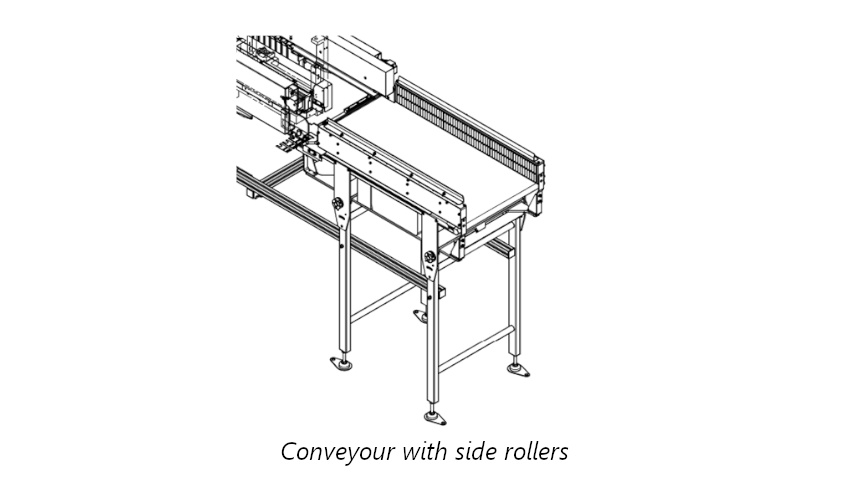

The customer received and evaluated the wrapping samples. The next step is to check the wrapping material the customer planned to use with the machine. We use special cold glue in the AR series. The glue is sprayed in mist to the bottom and lateral sides of the box. We normally recommend "fine paper", "pure white paper", "coated paper", and "art coated paper". On the other hand, the highly breathable paper such as Japanese ’Washi’ paper does not have good compatibility with the paper feeding unit, or the coated paper that the coating material is not cope with the glue should be examined if they can be run with the machine. The paper provided by the customer for this case is the shiny coated paper. Because this type of wrapping paper had poor glue adhesion and we had to deal with the situation that the side flaps were not glued properly. Therefore, we installed extra conveyor equipped with the side rollers after the wrapping machine so that the glued flaps are held longer with the side rollers until the glue is dried and this succeeded with the flap failures.

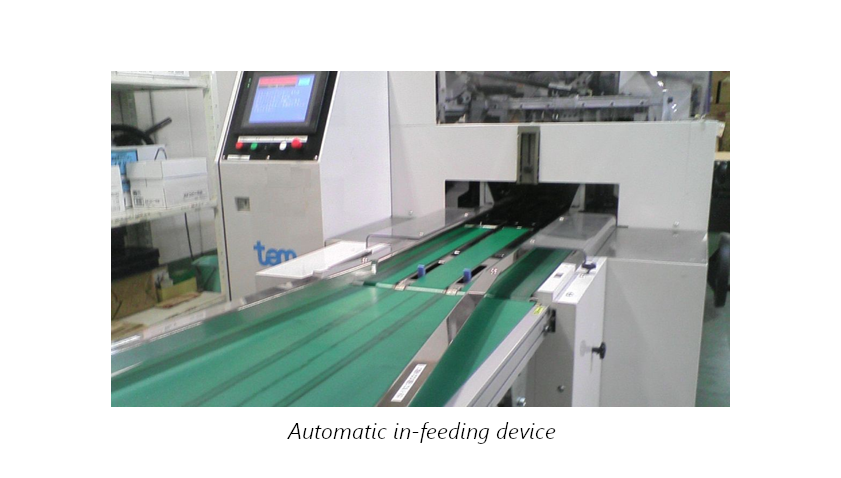

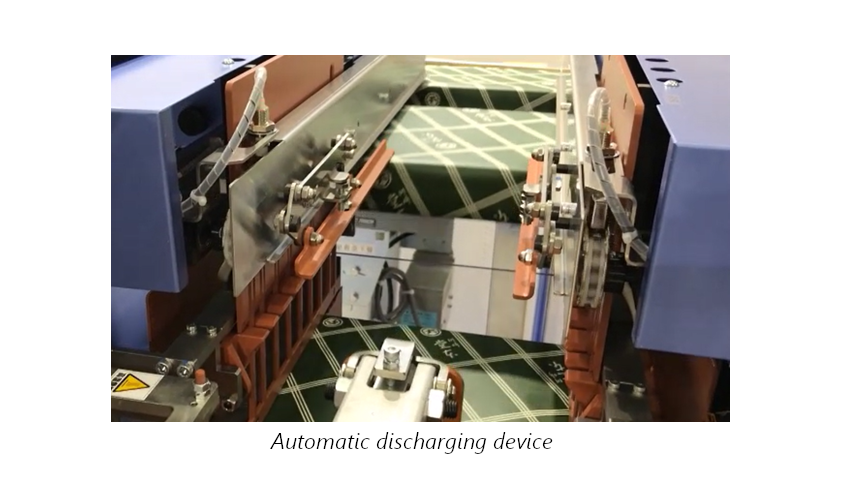

The customer had required the connecting system from the before-process and after process for their production line. The automatic in-feeding device at the entrance of the overwrapping machine and the automatic discharging device at the exit of the wrapping machine were connected. Thanks to these devices, the wrapping process can be carried out automatically without loading box at the feeding position or removing the box after wrapping by operator

■ Lastly

Not just the overwrapping machine, it is important the wrapping machine manufacturer like us to know the product better, test with the actual product, and propose the customer the real samples. Receiving the customer’s product grows our understanding the product, we can make more specific proposal, and eventually the customer can visualize the image if they purchase the machine. We, Tam can offers convincing proposition from our long year experiances and knowledges. Please feel free to contact us.

Tam Contact to: tam-overseas@tam-tokyo.co.jp