Tobacco Machinery

Created by our technological expertise based upon over 30years of experiences

We have a long experience in the field of cigarette filter rod machines. In addition, we have capabilities to supply various types of cigarette manufacturing machinery and equipment as introduced in the following part. Our machinery are actively operating in Japan at Japan Tobacco (JT) and Japan Filter Technologies (JFT).

Furthermore, our machinery have also been delivered to China, Korea and Taiwan.

Pneumatic Filter Rod Conveying System

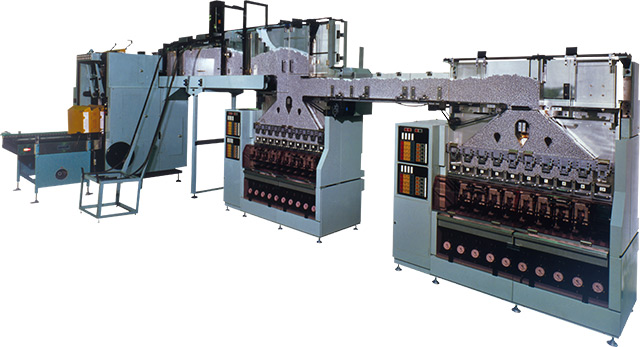

Pneumatic Filter Rod FeederFRFS

(FRFS 9-unit type)

Features

- 4 different unit number types available (6-, 9-, 10- and 12-unit)

- Optional specifications available

- Vertical Double-Drum system equipped for high speed and stable feeding operation

- Maximum feed speed of 2,750 rods/min. per unit

- Module design for easy maintenance

- Large scale control display with touch-panel function

- Capability of data output about machine operation to connect user's computer system

Filter Rod Receiver (Double-Receiving-Unit model)FRRJD

Max. receiving Capacity: 2,750 rods ⁄ min. per unit

Filter Rod Tray Unloader (for cardboard boxes)MTL57N

Max. handing capacity: 11.25 boxes/min.

Filter Rod Tray Unloader (for plastic trays)PT2

Max. handing capacity: 3.5 trays ⁄ min.

Filter Rod Reservoir SystemRF Series

Storage Capacity: Approx. 100,000 - 200,000 rods.

Pipe Line for pneumatic filter rod feederPipe Line

Design, Construction and technical consultation for pneumatic filter feed pipe line.

Filter Rod Packing

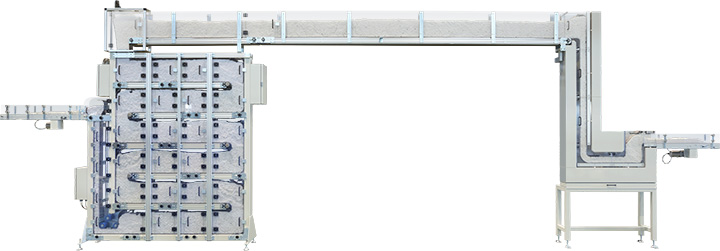

Filter Rod Packing systemFRP Series

Features

- All designed to fit your production plant layout

- Enhanced production efficiency due to high speed operation - Maximum output: 5 boxes/min.

(subject to change depending on material of cardboard box) - Compact and streamlined architecture

- LCD screen used for control display (standard equipment) - Easy-to-read display layout based upon the HMI (Human-Machine Interface) design

- The servo system provides high level of control accuracy.

- Materials can be continuously fed without stopping the machine.

Full Specifications linked widh filter maker

Packaging Process

Cigarette Packer & Caser

Film Overwrapper (for 10-pack-bundle)WE13

Output: 20 wrapped bundles/min.

"Eco-Pack" Machine (*)

Cardboard Caser (side loaded)SLC10

Output : 5boxes ⁄ min. (250 bundles ⁄ min.)

Film Overwrapper (for 10-pack-bundle)W4202

Output: 25 wrapped bundles ⁄ min.

"Eco-Pack" Machine (*)

Cigarette Can Filling MachineF22

Output: approx. 80 cans/min. (40-50 Cigarettes ⁄ can)

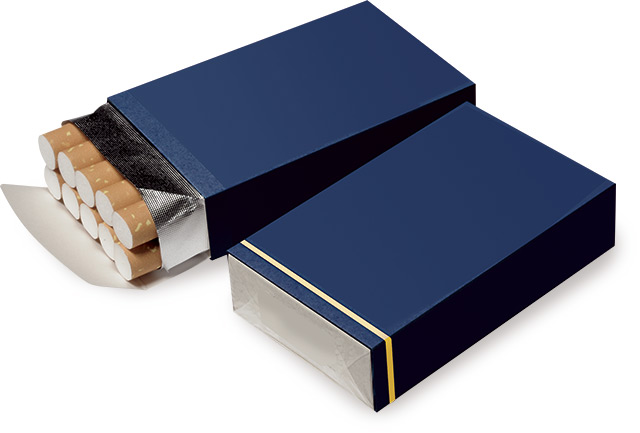

Shell & Slide Type Cigarette PackerS2

Film Overwrapper (for 5-pack-bundle)W48

Output: 60 wrapped bundles ⁄ min:

"Eco-Pack" Machine (*)Film Overwarpper (for cigarette pack)W322

Output: 300 packs/min.

* Economy and Ecology Pack by direct film wrapping for 5/10 packs without using paper box.