Features for ensuring safety

1. Standard equipment includes human-presence-detection device that can sense the presence of persons on the conveyor. (It can be added after.)

- Operators wear tag vests. Because the tags are embedded in the vest, risks are reduced when operators forget to wear the vests or when the detector is misfunctioning.

Visitors are required to wear tags. - No electric charging or maintenance is necessary.

- It’s perfect for work where very powerful and forceful motions are taking place.

2. All types of safety features have been incorporated in every part of our machines.

Tag-activation panel

Emergency stop occurs when activated.

Tags (No batteries needed)

Protects visitors from danger.

Senses when persons wearing tags slip and fall, shutting down the machine.

Tag Vest (No batteries needed)

Protects workers from danger.

Bundling Machine Side Cover

When opened, the bundling operation stops. If the cover is not properly closed, the bundling operation will not start.

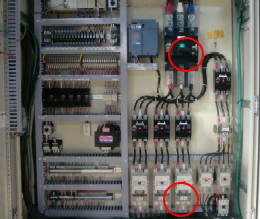

Upper : Short-circuit main breaker

Mounted on the baler. Offers sense of safety whenever the main breaker is turned off. Protects workers from accidents caused by electrical shocks.

Lower:Equipped with various breakers & 2E thermal

Prevents burnout caused by overheated motor.

Upper : Electromagnetic door lock

The door of the agitator stays locked electromagnetically until the agitator comes to a complete stop.

Middle: Door safety switch

The pin will not be freed to come out until the lock setting is released, so the door cannot be opened until the pin is freed.

Lower: Door remains completely locked by toggle clamps

Pull switch

The pull switch offers absolute safety, temporarily stopping the bundling function.

Barricade sensor

When the axel is in motion and the barricade sensor detects the presence of workers nearby, the machine stops immediately.