Baling Systems Series

For over 40 years, TAM has been contributing to the betterment of our natural environment through its eco-friendly baling systems that bale recyclable resources. Of course, our balers compact old newspapers, but in addition are fully capable of baling a variety of non-ferrous items that can be recycled and reused. As a result, they contribute to solving environmental issues.

When designing and developing our balers, we take into account all sorts of aspects such as the types and nature of materials to be baled, familiarizing ourselves with various needs. Each of our balers provides the same, high level quality of baling capabilities.

Our balers hydraulically compact and compress non-ferrous items such as newspapers and aluminum, compressing them to make them more compact. As a result, smaller bales reduce transport costs.

TAM can design and propose efficient balers, which can contribute to recycling scrap items and raising their commercial value. In this regard, TAM supports the recycling business.

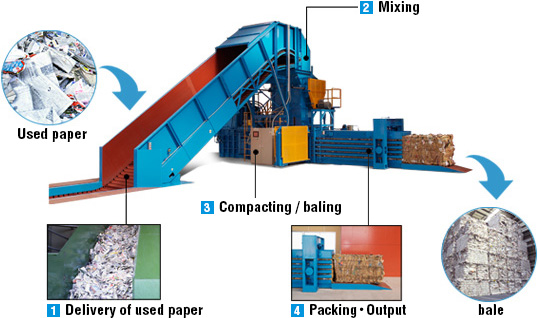

There are balers that can handle various scrap items such as old newspapers, magazines, industrial waste paper, copper, aluminum, precious metals and other items. We can build entire baling systems, which include feeders that deliver the scrap items, conveyors that transport them, hydraulic compactors that compress them, and machines that tie wires and complete the entire baling process. In addition, the bales can be compacted to various sizes so as to fit the specific dimensions of trucks and containers. This feature makes our balers even more efficient because they can recycle even greater amounts of resources.

Industrial Waste Balers ⁄ CompactorsRS Series

Features

Waste-paper balers ⁄ compressors come in a wide range of horse power, from 40 to 180.

We offer the best range of balers/compactors, from medium- to high-power machines, that optimally suit your needs for recycling waste-paper. TAM’s balers were designed with the idea of incorporating “all aspects of baling” such as density, size, and speed; as well as “cost aspects” such as initial investment costs, operating costs, and maintenance costs. We develop hydraulic waste-paper compactors (hydraulic pressure-packing machines), supporting our customers’ businesses by offering the best in terms of both quality and cost performance.

specifications

| Used-paper ⁄ waste-paper baler model |

Power | Conveyor | Baling Capacity (ton ⁄ h) |

Bale Sizes (mm) | No. of Bales | ||||

|---|---|---|---|---|---|---|---|---|---|

| Width (mm) |

Horizontal Length (mm) |

Angle (°) |

Width | Height | Length | ||||

| RSB25 | 180HP (45kW×3) | 1800 | 5000 | 35° | 25 | 1100 | 1100 | 2000 (free) | 5 |

| RS20 | 150HP (37kW×3) | 1700 | 5000 | 35° | 20 | 1000 | 1100 | 2000 (free) | 5 |

| RS15 ⁄ 10 | 100HP (37kW×2) | 1700 | 5000 | 35° | 15 - 10 | 1000 | 1100 | 2000 (free) | 5 |

| RS8 | 50HP (37kW×1) | 1700 | 4000 | 40° | 8 | 1000 | 1100 | 2000 (free) | 5 |

| RSS1 | 40HP (30kW×1) | - | - | - | 1.5 | 1000 | 1000 | 2000 (free) | 4 |

Hybrid Baling System

Features

The newly developed Hybrid Baler is extremely quiet and smooth running because it doesn’t have an agitator. As a result, even when it is running, workers near the machine can carry on conversations in their normal speaking voices. Its compact design enables it to be placed in tight spaces.

Compared to our former baling systems, it bales at a significantly higher density, reducing transport costs and running costs by over 10% (according to TAM’s own research).

specifications

| Models | Power | Conveyor | Baling Capacity (ton ⁄ h) |

Bale Sizes (mm) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Width (mm) |

Horizontal Length (mm) |

Angle (°) |

Width | Height | Length | Weight | |||

| HB100 | 100HP (37kW×3) | 1700 | 5000 | 35° | 12 | 1000 | 1000 | 2000 (free) | 1100 kg |

GTB Series

Features

The GTB series increases the weight of bales because it has greater power to firmly compress items at a higher density. As a result, this baler lowers transport costs and achieves a high level of productivity.

specifications

| Models | Power | Baling Capacity (ton ⁄ h) |

Bale Sizes (mm) | |||

|---|---|---|---|---|---|---|

| Width | Horizontal Length | Length | Weight | |||

| GTB60 | 60HP(45kW×1) | 3.2 | 1000 | 1100 | 1700 | 500 |

| GTB80 | 80HP(30kW×1) | 3.8 | 1000 | 1100 | 1700 | 500 |

Aluminum Baling System SeriesFive Star Baler

Features

The non-ferrous Five Star Baler was developed as a non-ferrous baler by Enterprise Company based in the USA. It can also be used to bale various types of non-ferrous scrap items. Depending on what is being baled, the computerized baler can automatically determine and control the degree of baling force, number of bundles, and volume to be fed. As the optimum non-ferrous, soft-press baler, the Five Star Baler can determine the right amount of baling force to apply to suit the types of materials being baled, as well as reduce the feed volume as needed.